Table of Contents

Toggle

To all the startups and designers who have brand aspirations but lack the ability to bring their products to life: We see you.

You have great ideas and brand concepts, perhaps scribbled on a napkin during a late-night burst of inspiration.

But the gap between a “sketch” and a “shelf-ready product” feels like a canyon.

You worry about quality, about IP theft, and about whether a factory will even take you seriously.

According to Forbes (The Hardware Startup Guide), bringing a physical product to market is one of the hardest business challenges.

Please listen to me: every successful brand begins with a dream.

Luxora exists to bridge that canyon. As your “Creative Ally”, we have the capability to turn your dream into reality.

This is a real-world case study. For a complete guide to our manufacturing models, read our Ultimate B2B Guide to Sex Toy Customization.

The Dream’s Starting Point: The Founder’s “Why”

It started with a moment of frustration.

Standing in a boutique, our partner (let’s call her Sarah) realized that nothing on the shelves reflected her vision of beauty, strength, or empowerment.

She saw plenty of products, but not one spoke to the bold confidence she wanted to see in herself.

Driven by this gap, she didn’t just critique—she created.

Late-night sketches became a manifesto for a new era of design.

Her “why” was never about chasing another generic launch, but about rewriting the standards themselves.

She believed, stubbornly and passionately, that a brand could make people feel powerful—right down to the packaging.

It’s that relentless pursuit of authentic aesthetics that set the foundation for her journey.

Our Co-Creation Journey: 5 Steps from “Sketch” to “Product”

Turning a concept into a tangible product requires a structured yet flexible process.

We broke down the journey into five distinct, collaborative stages.

Step 1: Concept Communication (The “Why”)

We began with deep listening sessions to immerse ourselves in her brand narrative.

This wasn’t a typical briefing; it was an excavation of the emotional core.

We needed to understand why this product needed to exist.

Step 2: Design Co-Creation (The “What”)

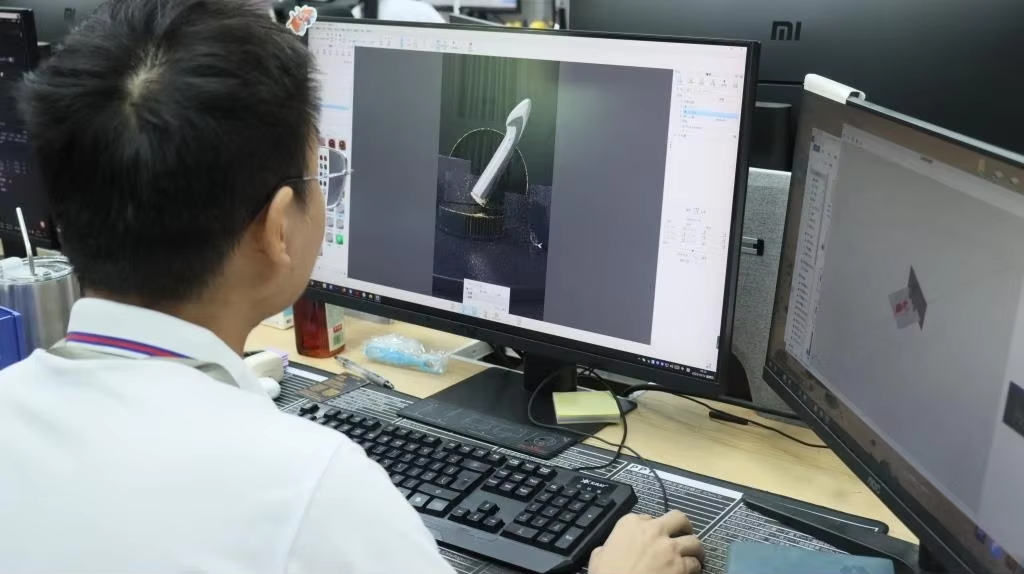

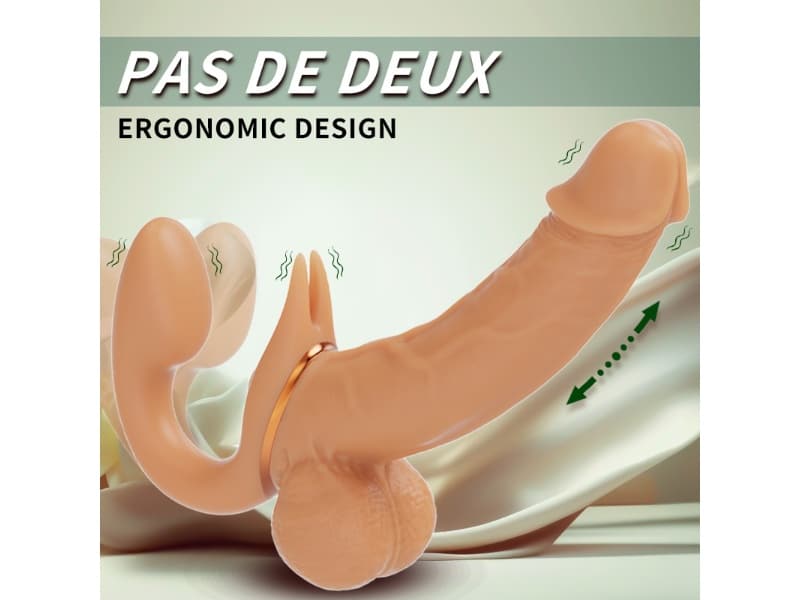

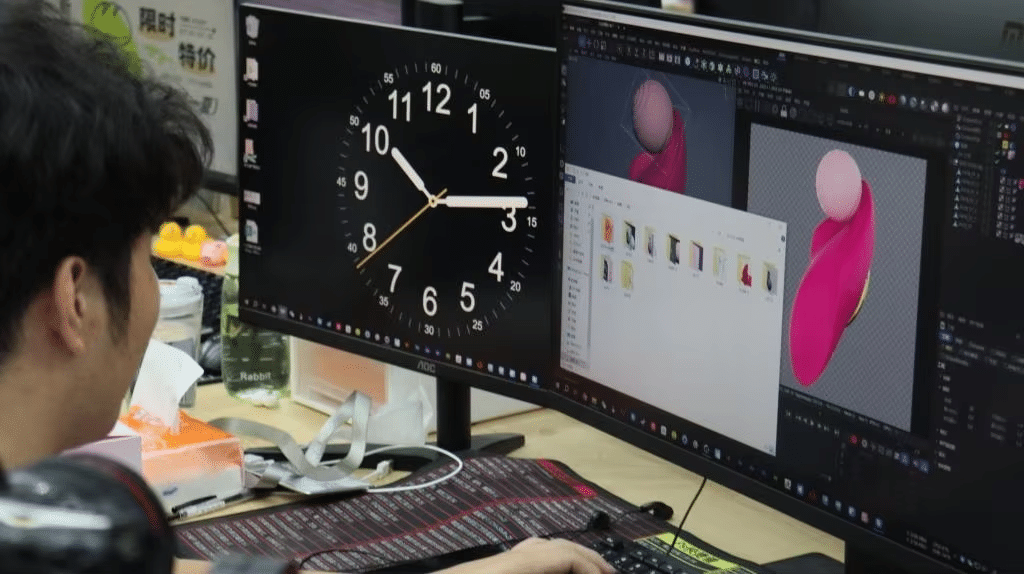

Our industrial designers translated her rough napkin sketches into sophisticated, manufacturable 3D models.

This phase was a dialogue between aesthetics and engineering, ensuring her philosophy survived the transition from paper to physical form.

Step 3: Technical Realization (The “How”)

Our engineers stepped in to match the design with robust internal structures.

This demanded creative problem-solving to achieve the exact tactile experience she envisioned while meeting rigorous safety standards.

Step 4: Sample Polishing (The Refinement)

Multiple prototype rounds became our collaborative laboratory.

Each iteration brought us closer to perfection. This is where her honest feedback and our technical expertise merged.

Step 5: Quality Production (The Scale-Up)

Finally, we implemented strict quality controls to scale her vision.

We established production protocols that treated each unit as an ambassador for her brand.

Luxora: Your Brand Dream’s “Accelerator”

Think of Luxora as more than a manufacturer; we are your launchpad. We bundle design, R&D, and packaging into a single, seamless solution.

| Our Service Commitment | What It Means For You (The Founder) |

| One-Stop OEM/ODM Solution | No need to juggle multiple vendors. From the initial sketch to the final packaged product, we manage the entire supply chain. |

| Airtight IP Protection | Your creativity is your most valuable asset. We sign strict NDAs and NNN Agreements ensuring your unique concept remains yours. |

| Startup-Friendly Flexibility | Big dreams often start small. We offer flexible MOQs, allowing you to test the market without the pressure of massive upfront investment. |

Conclusion: You Have the Dream, We’ll Handle the Details

The path from a napkin sketch to an empowering product isn’t meant to be walked alone.

Your role is to guard the vision and nurture the brand story.

Our role is to handle everything else.

This partnership model works because it honors what each side does best: your creative fire meets our manufacturing precision.

Frequently Asked Questions about OEM Partnership

Q1: From providing the design draft to receiving the first sample, how long does it usually take?

A1: Typically, it takes around 4-6 weeks to get the first physical sample after the design is finalized.

This timeline includes 3D modeling, material sourcing, mold creation, and the initial production run for the sample.

Q2: What is the payment process for OEM cooperation?

A2: Our standard process is a 50% upfront deposit to initiate the project (covering tooling and materials) and the remaining 50% balance upon your approval of the final sample, before we begin mass production.

Q3: What if I am not satisfied with the final sample?

A3: Your satisfaction is paramount.

If the sample doesn’t meet the agreed-upon specifications, we will work with you to identify the issues.

Our process includes up to two rounds of revisions to ensure we get it right before mass production.