Table of Contents

ToggleSourcing premium lesbian scissoring toys demands rigorous material oversight, as generic silicone often creates “lint-magnet” surfaces that drive RMA rates significantly higher.

Retailers frequently underestimate how quickly standard motors stall under the intense compressive force of tribadic contact, effectively destroying customer retention and brand equity.

In the 2026 market, LGBTQ+ consumers—who spend 13.4% more annually on wellness—are shifting their loyalty toward brands that prioritize medical-grade engineering over simple novelty aesthetics.

This guide benchmarks the top design archetypes against the Medical-Grade Platinum Silicone and High-Torque Tungsten Motor engineering standards.

We evaluate 2026 supply chains on 100-set MOQ flexibility and rapid lead times, ensuring you secure high-margin, anatomically precise inventory without aggressive capital risks.

1. The Aesthetic Evolution: From Realism to Identity Empowerment

Market trends have undergone a fundamental shift from anatomical realism to abstract, ergonomic forms.

Early inventory relied heavily on phallic shapes that failed the ergonomics of tribadism, often causing slippage or pinching.

The Philosophy of Inclusive Engineering

The current B2B standard has pivoted toward Inclusive Engineering.

This philosophy prioritizes flat, broad contact surfaces and flexible geometries that conform to the body.

For retailers, this aesthetic shift supports a “Sensory Art” value proposition.

Abstract designs reduce visual taboo, allowing high-end boutiques to merchandise these products as lifestyle accessories, driving sales among demographics who reject traditional novelty aesthetics in favor of identity empowerment.

Precision LSR Molding: Enabling Organic Geometries

Complex, fluid shapes require advanced manufacturing infrastructure.

Luxora leverages the Shenzhen-Dongguan industrial axis to implement elite Liquid Silicone Rubber (LSR) molding.

This method is critical for ensuring the structural integrity of thin, flexible wings used in tribbing toys, ensuring they survive repeated high-pressure use without tearing.

2. The 2026 Technical Portfolio: Top 5 Sourcing Archetypes

B2B success in this category relies on friction-resistant surfaces and non-stall motor performance.

| ID | Design Archetype | Engineering Milestone | B2B Value Proposition |

|---|---|---|---|

| 01 | The “Leaf” Wearable | 4-8hr Post-Cure Baking SOP | Eliminates lint attraction; zero chemical odor. |

| 02 | Dual-Motor “C” Wand | High-Torque Tungsten Motors | Anti-stall performance under partner body weight. |

| 03 | ENIG Smart-Sync Vibe | 4-Layer Immersion Gold PCB | Zero oxidation; stable app connectivity in heat. |

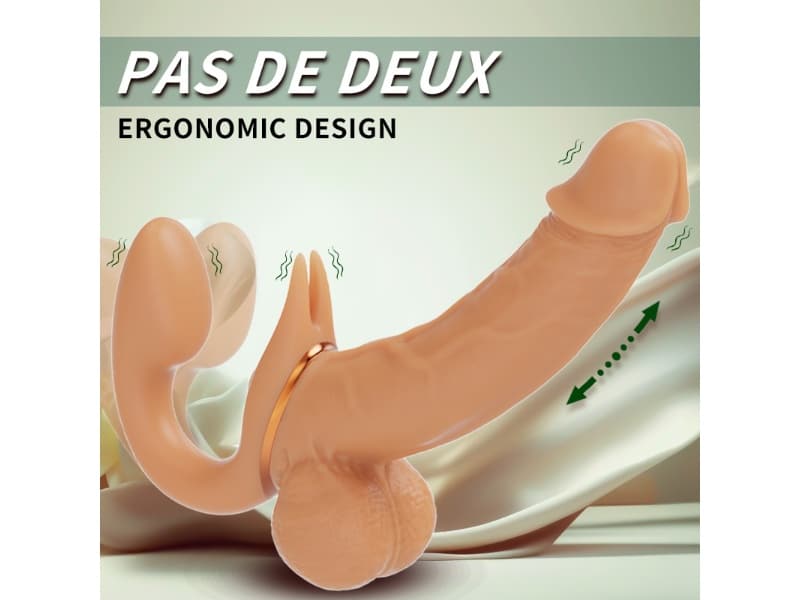

| 04 | Strapless-On Hybrid | Precision LSR Muscle-Retention Bulb | Hands-free stability; prevents mid-session slippage. |

| 05 | The Rigid Grinder | IPX8 Submersion-Sealed Core | Zero water ingress; industrial-grade durability. |

3. Engineering the “Non-Stall” Experience

Scissoring tech often fails on power distribution. Most generic devices utilize weak motors that stall when compressed between two bodies during tribal contact.

The High-Torque Tungsten Solution

Luxora resolves this by implementing High-Torque Tungsten Motors.

Unlike standard iron-core motors, tungsten powerplants provide the necessary torque to maintain consistent vibration frequencies even under significant physical resistance.

This is paired with a high-elongation silicone formulation that preserves structural memory, preventing the device from “bottoming out” under load.

Signal Integrity with ENIG Gold PCBs

App-controlled wearables are a high-margin sector, yet they suffer from signal dropouts caused by moisture and body mass shielding.

We mandate 4-layer ENIG (Immersion Gold) PCB finishes.

Gold plating prevents oxidation on the PCBA, guaranteeing that the Bluetooth module remains 100% responsive, which is critical for protecting your brand’s reputation in the luxury smart-toy segment.

4. Material Purity: The “Soft-Touch” Sensory Standard

Surface integrity defines premium market positioning.

While generic silicone acts as a “lint magnet,” Luxora enforces a medical-grade standard that prioritizes hypoallergenic safety.

The Deodorization SOP

Cheap silicone toys often retain a chemical “factory smell” due to trapped Volatile Organic Compounds (VOCs).

This is a primary driver for returns in the wellness segment.

We implement a mandatory 4-8 hour Post-Curing Industrial Baking Cycle.

This process drives out VOCs, ensuring a neutral scent profile and a smooth, non-tacky finish essential for high-end retail.

5. Supply Chain Strategy: 100-Set MOQ & 7-Day Velocity

Efficiency in the Shenzhen-Dongguan axis allows Luxora to bridge the gap between boutique brand needs and massive factory requirements.

-

Capital Efficiency: Our 100-set MOQ allows you to test custom ergonomic designs without a six-figure capital commitment.

-

Pride-Season Velocity: We leverage a 7-day rapid restock protocol, ensuring you never miss a sale during vertical demand spikes like Pride Month.

-

Logistics Optimization: By utilizing HS Code 9019.10.10 (Massage Apparatus), we help distributors secure lower duty rates and smoother customs clearance, optimizing your total landed cost.

High-Performance Gay Wellness Tech For Brands

Final Thoughts

Choosing “Inclusive Engineering” ensures you capture the higher spending power of the lesbian and inclusive demographic without risking your brand reputation on stalling motors or chemical odors.

Premium, anatomical inventory commands immediate loyalty and protects your store from price wars.

Frequently Asked Questions

What is the standard design baseline for scissoring toys?

Market-ready scissoring toys typically rely on a dual-ended architecture.

The standard configuration pairs a 2.75-inch insertable bulb for internal anchoring with an external clitoral ring or pad.

This design facilitates hands-free mutual stimulation during tribbing (vulva-to-vulva contact). Ergonomic stability is the primary differentiator here; cheaper models often slip during friction, while premium molds maintain position without manual adjustment.

Are scissoring vibrators typically waterproof?

Entry-level models often stop at IPX4 (splash-proof), but strict B2B manufacturing standards dictate an IPX7 rating for complete submersion up to 1 meter.

Achieving this requires precise sonic welding or silicone overmolding to seal the PCBA and motor housing against water ingress.

Distributors should reject units that rely solely on gaskets, as they often fail in bath or shower environments.

How do multi-motor systems improve shared stimulation?

Single-motor designs suffer from vibration dampening, where power weakens significantly at the toy’s extremities.

Advanced scissoring tech employs dual independent motors—typically one in the internal bulb and one in the external arm.

This engineering ensures both partners experience consistent, high-torque vibration intensity without the “buzzy” sensation common in lower-cost alternatives.

What materials are required for safety compliance in this category?

Distributors must strictly require non-porous, medical-grade platinum silicone. Unlike TPE or TPR, platinum silicone is hypoallergenic, boil-sterilizable, and free from phthalates.

High-tier manufacturing also includes a post-curing baking cycle to eliminate volatile organic compounds (VOCs) and chemical odors, ensuring compliance with general consumer safety standards like CE and RoHS.

Why is battery life a critical pain point for wearable vibrators?

Scissoring toys must fit between bodies, necessitating compact, slim profiles that limit battery size.

The industry average runtime hovers between 60 to 80 minutes.

Premium engineering optimizes PCB power management and utilizes high-density lithium cells to extend operation up to 150 minutes, mitigating the risk of mid-session power failure.