Table of Contents

ToggleSecuring medical-grade anal beads for men is the critical firewall against high B2B return rates in 2026.

While porous TPR (Thermoplastic Rubber) options offer lower entry costs, they often fail mechanical stress tests at the retrieval loop, destroying dealer margins through inevitable warranty claims and connector breakage.

This analysis benchmarks inventory against the Luxora “Anatomical Precision” standard, prioritizing single-shot Liquid Silicone Rubber (LSR) molding for monolithic structural integrity.

We examine platinum-cured biocompatibility and flexible 100-set MOQs to help you distinguish safe, medical-grade tools from hazardous novelty items.

1. Market Drivers: Prostate Stimulation and Graduated Training

The gay male demographic increasingly approaches anal beads as functional instruments for wellness rather than visual novelties.

The primary driver for high B2B volume in this sector is “graduated training”—a process where users rely on specific progressive diameters to safely relax the sphincter and access the prostate gland (P-spot).

Unlike general adult toys that prioritize surface aesthetics, this niche validates products based on anatomical utility.

Professional buyers are rapidly pivoting to non-porous platinum-cured silicone to meet the hygiene requirements of a health-conscious community that values long-term biocompatibility over initial low cost.

2. Engineering Standards: LSR vs. Standard Compression Molding

The manufacturing method dictates the lifespan of the product and its resistance to bacterial colonization.

| Manufacturing Detail | Generic Compression Molding | Luxora Liquid Injection (LSR) |

|---|---|---|

| Surface Integrity | Visible flash lines/abrasive ridges | Seamless, zero-flash finish |

| Loop Strength | Glued/Bonded connectors (High fail risk) | Monolithic (Single-Shot) structural unit |

| Material Hygiene | Porous TPE/PVC (Bacterial retention) | 100% Non-porous Platinum Silicone |

| Post-Processing | No baking (High VOC/Chemical odor) | 4-8 Hour Industrial Deodorization Cycle |

3. Pull-Loop Engineering: Preventing Structural Breakage

Mechanical failure in anal beads rarely occurs in the beads themselves; it strikes the connector between the last bead and the retrieval loop.

During extraction, the anal sphincter applies significant retention force. If the loop is a separate component attached via adhesives, this creates a specific point of failure.

Transverse Stress and ASTM D2990 Compliance

Luxora eliminates this risk by creating the entire strand—beads, cord, and retrieval loop—as one continuous molecular unit.

-

Monolithic Construction: Single-Shot LSR molding removes the physical seam where breakage typically occurs.

-

Tensile Memory: Using Medical-Grade Platinum Silicone ensures that the connector does not stretch beyond its elastic limit (Material Creep), maintaining its shape after repeated retrieval cycles.

-

Tear Strength: Our high-tear-strength LSR formulas are specifically calibrated for the gay male market, where high-pressure sphincter contractions are a design requirement.

4. 2026 Product Portfolio: 8 Best-Selling Designs

B2B buyers should maintain a 75/25 inventory split favoring graduated profiles to satisfy the high volume of “Self-Discovery” consumers.

| ID | Design Archetype | Technical Milestone | B2B Value Proposition |

|---|---|---|---|

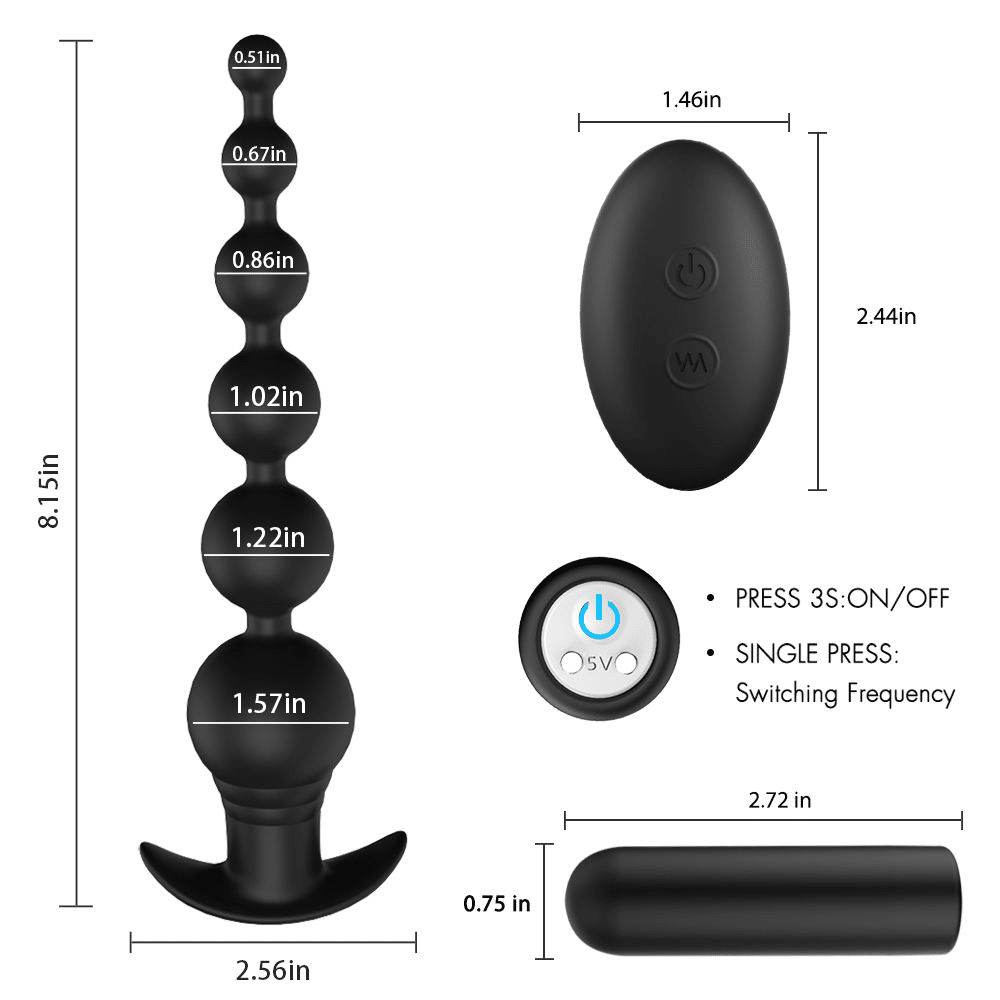

| 01 | Progressive Trainer | 0.5″ to 1.5″ Graduated Progression | Volume driver for beginners; eases intimidation. |

| 02 | Advanced Rhythmic | Consistent 1.25″ Uniform Spheres | High-sensation for experienced power users. |

| 03 | Vibrating Tungsten Core | High-Torque Anti-Stall Motor | Penetrates muscle tension without losing power. |

| 04 | Geometric Texture | Seamless LSR Haptic Ridges | Proprietary sensation profile; defensible USP. |

| 05 | Flexi-Strand Hybrid | High-Elongation Platinum Silicone | Survives 180° flex tests; zero structural fatigue. |

| 06 | Prostate Targeter | Precision P-Spot Curve Geometry | Functional wellness tool for therapeutic play. |

| 07 | Pure Air Minimalist | VOC-Free Industrial Baking | Captures health-conscious eco-segments. |

| 08 | Weighted Performance | Encapsulated Medical-Grade Steel | Provides internal “fullness” without porosity. |

5. Sourcing & Logistics: Maximizing Landed Cost ROI

Efficiency in the Shenzhen-Dongguan axis allows Luxora to provide medical-grade quality at competitive B2B tiers.

-

HS Code 9019.10.10: We classify anal beads for men as “Massage Apparatus” rather than “Toys.” This strategy often secures lower duty rates and smoother customs clearance for wellness-positioned brands.

-

Blind Shipping: We strip all manufacturer identification from the logistics trail to protect your profit margins and prevent channel conflict.

-

100-Set MOQs: We enable brands to test proprietary haptic textures without the capital risk of 1000+ unit orders.

-

7-Day Lead Time: Our high-speed production lines ensure you can react to viral trends and Pride-season surges instantly.

Source High-ROI LGBTQ+ Wellness Tech

Final Thoughts

Choosing “Inclusive Engineering” ensures you capture the higher spending power of the gay demographic without risking your reputation on hygiene complaints or structural failures.

Premium, seamless, and VOC-free inventory commands immediate loyalty and protects your store from price wars against generic competitors.

Frequently Asked Questions

What are the best types of men’s anal beads for safety and durability?

The most reliable engineering standard uses a graduated design, starting with small diameters (under 1 inch) to allow progressive sphincter accommodation.

We mandate the use of non-porous, platinum-cured medical-grade silicone rather than TPE or jelly, which eventually degrade and harbor bacteria.

A reinforced flared base or pull-loop is an absolute anatomical requirement to prevent accidental retraction into the rectum.

Why do anal beads frequently snap during use?

Breakage is usually a failure of “Assembled Engineering.”

Generic beads use glue to attach the retrieval loop.

Luxora solves this with Monolithic LSR Molding, creating the entire strand as a single structural unit that distributes retrieval tension evenly.

How do you ensure the product is odorless?

Every unit undergoes a mandatory 4-8 hour Post-Curing Industrial Baking Cycle.

This process drives out Volatile Organic Compounds (VOCs) that cause the “chemical smell” associated with cheaper production lines.