Table of Contents

ToggleIn the competitive landscape of B2B adult wellness, the choice between platinum silicone vs. TPE is the single most significant factor determining a retailer’s long-term profitability.

While generic TPE (Thermoplastic Elastomer) units offer lower entry-level pricing, they often harbor hidden costs: chemical leaching, bacterial absorption, and toxic odors.

For a brand owner, these technical failures translate directly into high RMA (Return Merchandise Authorization) rates and a destroyed reputation.

This guide benchmarks material integrity against the Medical-Grade Platinum Silicone standard.

We examine why post-curing deodorization is a mandatory firewall against “Dead on Arrival” reviews and how investing in non-porous materials is your strongest defense against market recalls.

1. The Chemical Divide: Why Porosity is a B2B Liability

The primary difference between these materials lies in their molecular structure.

TPE is essentially a “microscopic sponge.” Even when it appears smooth to the naked eye, it possesses micro-pores that act as reservoirs for bacteria, lubricants, and bodily fluids.

The Toxicity Trap of TPE

-

Phthalate Migration: Generic TPE often relies on oil-based plasticizers to achieve its characteristic softness. Under body heat, these chemicals can leach out, causing irritation or chemical burns on sensitive mucous membranes.

-

Bacterial Harboring: Because TPE cannot be sterilized in boiling water (it deforms or melts), it develops a “bio-film” over time. This triggers lingering smells that users notice even after washing.

-

VOC Off-gassing: Budget factories skip the essential degassing steps, leaving products with a strong, toxic rubber smell. In the B2B sector, this odor is a commercial liability that leads to immediate customer dissatisfaction.

2. Engineering Standards: Material Performance Comparison

To help distributors evaluate inventory quality, we have structured a technical benchmark comparing Luxora’s standards against the mass-market average.

| ID | Performance Metric | Luxora Platinum Silicone | Mass-Market TPE/TPR |

|---|---|---|---|

| 01 | Surface Porosity | 100% Non-porous (Biocompatible) | High porosity (Bacteria trap) |

| 02 | Thermal Stability | Boilable (Zero deformation) | Melts/Warps above 60°C |

| 03 | Odor Profile | Neutral “Pure Air” Finish | Toxic “Burnt Rubber” smell (VOCs) |

| 04 | Chemical Leaching | Hypoallergenic (Inert) | Potential Phthalate/Oil migration |

3. The Economics of Quality: Reducing the Loss Ratio

In the adult industry, the true cost of a product is not the purchase price; it is the Purchase Price + Return Rate + Customer Acquisition Cost.

The “DOA” Refund Problem

When a consumer receives a product with a strong chemical smell, they often categorize it as “Dead on Arrival.”

This triggers a refund cycle that erases the 15-20% margin gain initially sought by sourcing cheaper TPE.

Luxora’s Low-RMA Engineering addresses this by using 100% platinum-cured silicone that eliminates sensory rejection.

By protecting your brand equity, we ensure that a single sale leads to a repeat customer rather than a one-time refund headache.

4. The 4-8 Hour Deodorization SOP: The Science of “Pure Air”

Many factories rush the production cycle to save on energy costs, packaging products immediately after they leave the mold.

This traps residual catalysts and Volatile Organic Compounds (VOCs) inside the material.

Luxora’s Post-Curing Protocol

We mandate a 4-8 hour Industrial Baking Cycle for every unit. This secondary processing phase uses sustained heat to accelerate the evaporation of all non-solid particles.

-

Molecular Stability: The material becomes 100% physically inert.

-

Hypoallergenic Finish: Stripping away VOCs ensures the product is safe for immediate use on sensitive mucous membranes.

-

Odor Neutralization: Ensures a professional, neutral unboxing experience—a critical trust anchor for high-end retail.

5. Tactical Identification: The Pinch and Burn Tests

For B2B buyers inspecting warehouse stock, there are two quick methods to verify material purity.

-

The Pinch Test: Pinch the silicone hard and twist it. If the fold turns white, the material contains plastic fillers or calcium carbonate. Pure medical-grade silicone will maintain its color even under extreme tension.

-

The Burn Test: For definitive verification, burn a small sample. Pure platinum silicone produces white smoke and leaves a white, brittle ash. TPR or plastic blends emit thick black smoke and leave a sticky, black residue that smells like burnt tires.

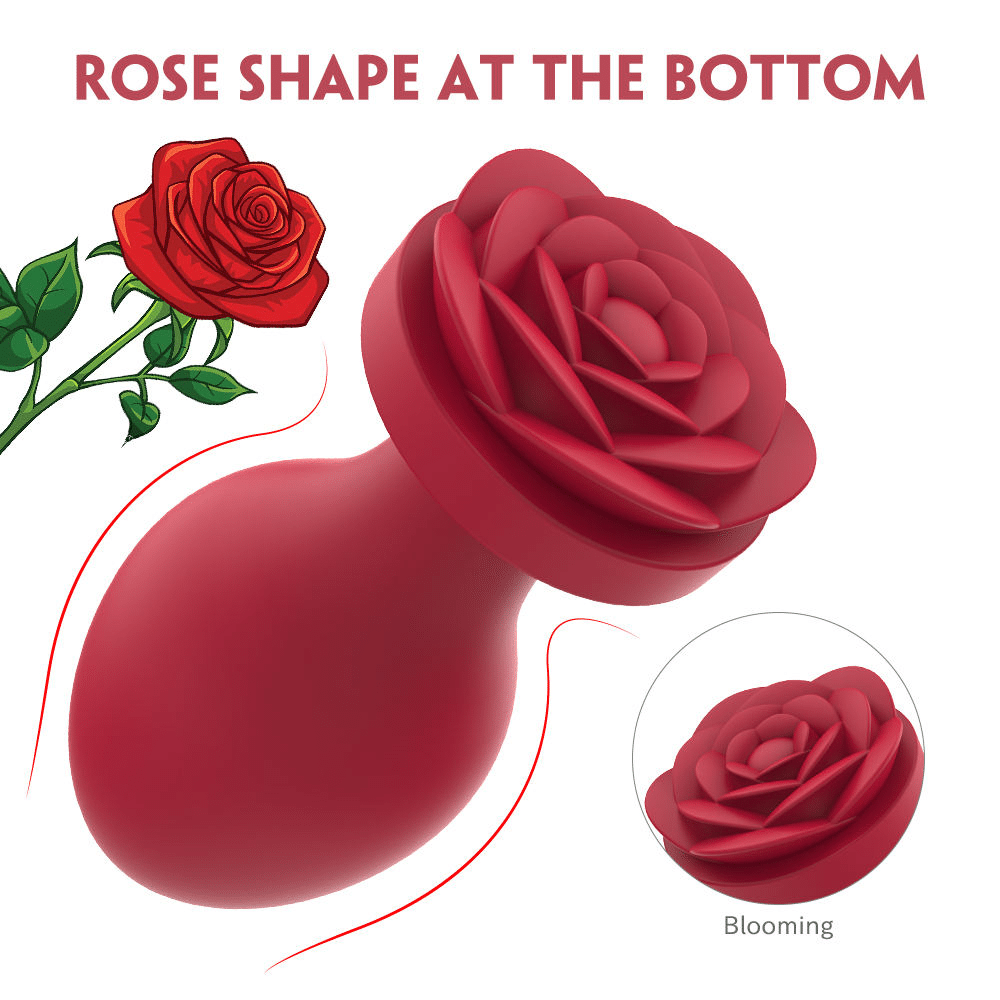

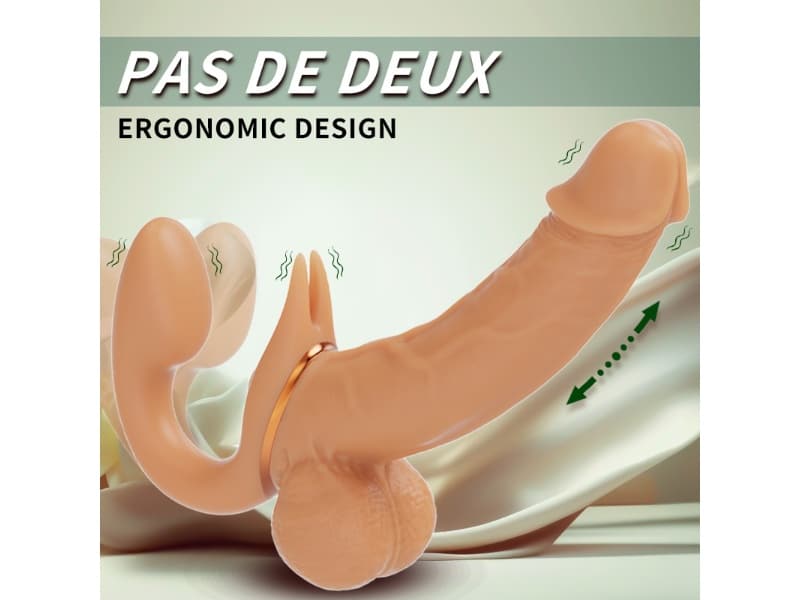

Anatomically Precise Gay Wellness Tech Solutions

Final Thoughts

Investing in the best material for anal toys remains your strongest defense against market recalls and negative hygiene reviews.

Sourcing generic TPE might reduce initial PO costs, but the long-term liability of bacterial absorption destroys brand value.

High-margin inventory requires the safety assurance of Luxora’s Medical-Grade Platinum Silicone, eliminating the VOC odors that drive “Dead on Arrival” returns.

Frequently Asked Questions

Is platinum silicone or TPE better for anal toys?

Platinum-cured silicone is the only viable commercial standard for internal use.

It offers high thermal stability (-60°C to 200°C+), allowing for sterilization without degradation.

TPE is cost-effective for external sleeves but dangerous for anal play; its porous structure traps bacteria, and it deforms under the heat required to clean it properly.

For B2B distribution, silicone ensures lower liability and lower return rates.

What is “platinum-cured” silicone actually?

This refers to the catalyst used during the curing process.

Platinum curing uses a platinum catalyst rather than a peroxide one.

This eliminates toxic by-products, resulting in a material that is odorless, tasteless, and exceptionally pure.

At Luxora, we take this further with a mandatory 4-8 hour Post-Curing Industrial Baking Cycle to drive off any volatile organic compounds (VOCs), ensuring a “Pure Air” experience out of the box.

Why is “Medical-Grade” critical for anal products?

Anal tissue is mucous membrane—highly absorbent and lacking the protective keratin layers found on external skin.

This means any chemical leaching from a toy enters the bloodstream rapidly.

Medical-grade materials are non-porous and biocompatible, preventing the absorption of phthalates or plasticizers.

They also resist bacterial growth, which is non-negotiable for preventing bio-film buildup and subsequent infections.

Can TPE toys cause customer rashes?

Yes. Uncertified or generic TPE often relies on phthalates or oil-based plasticizers to achieve softness.

These chemicals are known allergens and can trigger allergic dermatitis or chemical burns when left in contact with sensitive mucous membranes.

While “medical-grade TPE” exists, the vast majority of budget sexual wellness products use lower grades that fail strict biocompatibility tests.

How can I verify if a product is 100% silicone?

The “Pinch Test” is the quick field check: pinch the material hard.

If the fold turns white, it contains fillers. Pure silicone keeps its color.

For definitive warehouse verification, burn a small sample. Pure silicone produces white smoke and leaves white ash.

Plastic blends or TPR emit black smoke and smell like burnt tires.

What is the best material for sensitive users?

Medical-grade, platinum-cured silicone is the safest baseline.

It is hypoallergenic, chemically inert, and compatible with water-based lubricants.

Its hyper-smooth surface minimizes friction, which is vital for preventing micro-tears in users with sensitive tissue or those new to anal play.

This material choice directly supports our “Inclusive Engineering” philosophy by ensuring safety for all body types.