Table of Contents

Toggle

If you are a high-end brand with the ultimate pursuit of product quality, and if you still think “silicone is all the same,” then we need to have a good chat today.

In addition to vision and function, touch is the most direct and intimate dialogue between erotic products and users.

But a “velvet-like” touch is not a simple slogan; behind it is the rigorous combination of material science and craftsmanship.

At Luxora, we believe material is the medium of “Sensory Art”.

We don’t just mold plastic; we engineer feelings.

This article explores material science. For a complete guide to our engineering capabilities, read our Ultimate B2B Guide to Sex Toy Innovation.

The Science of “Touch”: Hardness, Resilience, and Surface Treatment

The perfect touch isn’t an accident; it’s a precise balance of three key material properties.

We manipulate the polymer’s crosslinking density and apply specialized finishing techniques to create a texture that feels impossibly soft and lifelike.

1. Shore Hardness

This measurement defines the material’s resistance to indentation.

According to ASTM International Standards, Shore Hardness is critical for determining flexibility.

In platinum-cured silicone, we can precisely control the final Shore rating by carefully manipulating the catalyst. Even small changes create dramatically different sensory experiences.

2. Rebound Rate

This determines how quickly the silicone returns to its original shape after being compressed.

A high rebound rate creates a vibrant, “flesh-like” resilience, while cheaper materials can feel lifeless and dull.

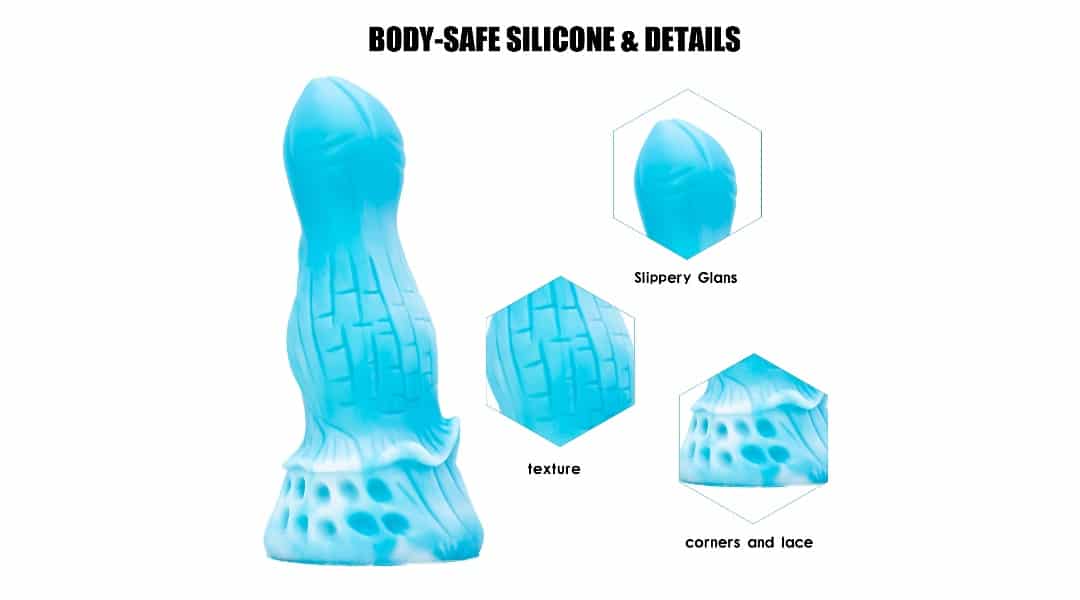

3. Surface Treatment

This is the final frontier.

We transform clinical smoothness into a velvet-like texture using a multi-layer matte coating process.

This specialized technique creates microscopic surface variations that feel incredible against the skin while maintaining the material’s non-porous integrity.

How Hardness Translates to Experience:

| Shore Hardness | Tactile Sensation | Best For Users Seeking… |

| Shore 00-50 | Extremely soft, almost gel-like and yielding. | A gentle, enveloping, and ultra-delicate experience. |

| Shore 0A | The sweet spot, mimicking natural skin elasticity. | A perfect balance of softness and gentle resistance. |

| Shore 10A | Firmer with a more structured, resilient feel. | Substantial tactile feedback and a “bouncy” quality. |

Luxora’s “Touch Lab”: Our R&D Process

Creating a signature touch is a journey of meticulous refinement.

Our process is designed to bridge the gap between hard data and the subjective, emotional experience of touch.

After handling hundreds of “good enough” samples over the years, you learn to instantly feel the difference between simple manufacturing and true craftsmanship.

Our R&D Journey Follows Three Critical Stages:

-

Material Sourcing & Vetting: We begin by systematically evaluating platinum-grade silicone formulations from the world’s leading suppliers. Each material undergoes rigorous testing for tensile strength, elongation, and what we call “skin-mimicry.”

-

Formula Optimization & Micro-Tuning: Our engineers make incremental adjustments to platinum catalyst concentrations. It’s a delicate dance to achieve the perfect rebound rate and texture while ensuring long-term stability.

-

Blind Tactile Evaluation: Data is important, but human perception is everything. We conduct blind tests with trained sensory assessors who rank materials based solely on touch, without any visual cues.

Customizing a Unique “DNA Touch” for Your Brand

We offer two distinct paths to help you build your brand’s unique sensory identity, transforming a simple preference into exclusive intellectual property.

For Speed-to-Market: Our Validated Formulation Library

We offer a comprehensive portfolio of proven touch formulations, from gossamer-soft Shore 00 to resilient Shore 15A compounds.

These are ready for immediate deployment, allowing you to launch quickly without compromising on tactile sophistication.

For Ultimate Exclusivity: Co-Developed “Signature Touch”

Our ODM collaboration process is an intensive partnership.

Your brand team works directly with our materials engineers to define and create a legally protected “signature touch” formulation.

The resulting formula—with its proprietary mixing ratios—becomes your core asset. We guarantee it will never be replicated for another client.

Conclusion: Touch is the Ultimate Luxury

In the adult sex toy market, touch transcends all other senses.

It cannot be adequately described in marketing copy.

It cannot be faked by competitors.

It has become the most powerful and defensible brand asset you can own.

While aesthetics can be copied and features replicated, the molecular architecture of a memorable tactile experience is an insurmountable barrier to commodity competitors.

Luxora’s Touch Lab is your pathway to creating that unforgettable experience.

We can help you claim this advantage before your competitors even realize its transformative potential.

Ready to engineer a feeling? Talk to a LUXORA expert about your custom silicone needs today.

Frequently Asked Questions (FAQ)

Q1: Is softer silicone always better?

A1: Not necessarily.

The ideal hardness depends on the product’s design and the desired user experience.

Different Shore hardness levels (e.g., 0, 5, or 10) create distinct sensations.

While softer silicone can feel more yielding, a slightly firmer material might provide a better “bouncy” or “fleshy” feel, which many users prefer.

Q2: What is “dual-layer silicone” technology and how does it affect the touch?

A2: Dual-layer silicone technology involves combining two different layers of silicone—typically a softer outer layer with a firmer inner core.

This mimics the feeling of real skin, providing a gentle, yielding surface with a firm, resilient structure underneath, creating a more complex and realistic tactile experience.

Q3: Can clients specify a desired touch in an ODM project?

A3: Absolutely. We encourage our ODM partners to define their ideal tactile experience.

You can choose from our existing range of mature touch formulas, or we can co-develop an exclusive, non-replicable “signature touch” for your brand, making it a core asset of your product line.