Table of Contents

ToggleSourcing compliance-verified gay anal sex toys constitutes the primary defense against negligence liability and expensive recalls in the 2026 market.

Failing to mandate non-porous material standards exposes distributors to surgical extraction lawsuits caused by inadequate “vacuum effect” safeguards or toxic chemical hazards.

For professional buyers, the distinction between a “novelty” item and a “wellness device” is defined by adherence to strict engineering protocols that protect both the end-user and the dealer’s net margins.

This analysis benchmarks production quality using the strict ISO 3533:2021 anatomical safety standard.

We validate Medical Grade Platinum Silicone biocompatibility and examine FDA 21 CFR 177 certification protocols to help you secure a high-margin, zero-risk supply chain for the long term.

1. The High-Risk Nature of Anal Toy Sourcing

Many B2B buyers underestimate the specific liabilities attached to low-cost “jelly” or standard TPR (Thermoplastic Rubber) novelties.

Unlike general vibrators used externally, anal products require absolute material purity because the rectal mucosa absorbs chemicals significantly faster than external skin.

The Toxicity Trap: Porous Materials and Phthalate Migration

Cheaper compounds effectively act as microscopic sponges, creating safety hazards that lead to product recalls.

-

Microbial Entrapment: Porous materials like standard TPR and PVC create microscopic breeding grounds for bacteria and mold that users cannot fully sterilize, leading to recurring infections.

-

Chemical Leaching: Low-tier compounds often suffer from phthalate migration. As body heat increases during use, chemical softeners degrade and leach directly into the body.

-

Structural Failure: These materials degrade rapidly, becoming sticky or developing surface cracks within 6-8 months, which spikes return rates and destroys brand trust.

Mitigating Risk with Platinum-Cured SOPs

At Luxora, we bypass “food grade” shortcuts in favor of medical-grade biocompatibility.

Every unit leaving our Shenzhen-Dongguan facilities undergoes a mandatory 4-8 hour Post-Curing Industrial Baking Cycle.

This process is essential to force out Volatile Organic Compounds (VOCs), eliminating the “factory smell” and ensuring a truly hypoallergenic product.

2. Engineering Standards: Verified vs. Generic Claims

To assist B2B buyers in the vetting process, we have structured a technical comparison based on industrial failure testing.

| Vetting Criteria | The Generic Claim (Risk) | The Verified Standard |

|---|---|---|

| Material Safety | “Eco-Friendly” / TPR Label | FDA 21 CFR 177 + Platinum Cured |

| Chemical Limits | “Non-Toxic” Marketing Copy | RoHS Report (Pb/Hg/Cd Limits) |

| Odor & VOCs | Basic Surface Wash | 4-8 Hr Post-Cure Industrial Baking |

| Quality System | Factory “Promise” | ISO 9001:2015 Traceability |

3. Understanding ISO 3533:2021 Safety Mandates

ISO 3533:2021 is the first international standard to enforce a medical-device approach to sex toy safety.

It separates professional manufacturing from “novelty” production by requiring manufacturers to document hazards from the design phase through to post-market surveillance.

Thermal Safety and Electrical Integrity

Under the standard, heated products must incorporate NTC sensors and auto-cutoff mechanisms to cap surface temperatures at 48°C.

This prevents deep-tissue burns that can occur without the user noticing due to the limited nerve endings in certain rectal zones.

Additionally, internal battery systems require Multi-layer PCBs with ENIG finishes to ensure 100% signal stability and fire risk mitigation.

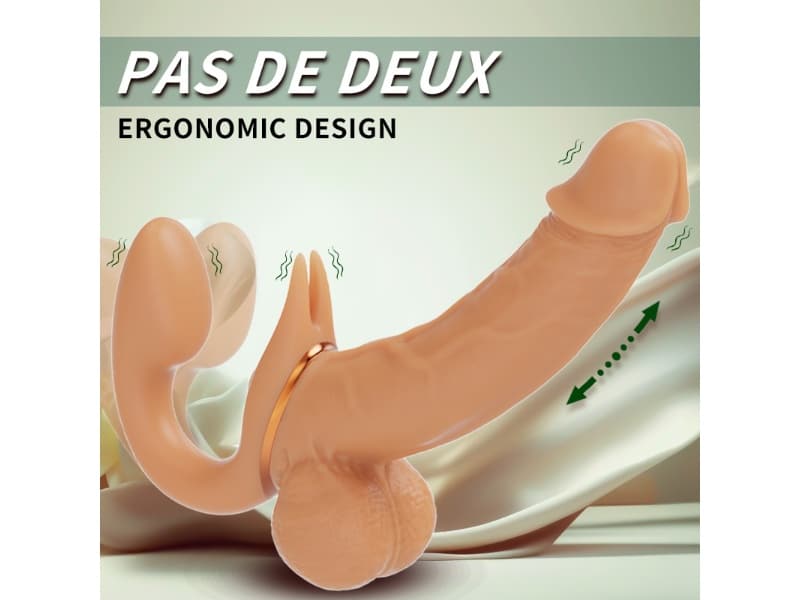

Annex B Compliance: Preventing Anal Retention

Annex B specifically addresses the “vacuum effect” risks. The rectum is an involuntary muscle ring that can create a powerful pull during stimulation.

-

Mandatory Retrieval Features: Anatomically flared bases are a binary pass/fail metric. If a device clears the sphincter barrier, manual retrieval becomes impossible due to the sigmoid colon’s anatomy.

-

The 50% Ratio: Luxora applies a geometric consensus: the base diameter must be at least 50% wider than the thickest part of the insertion shaft to provide a physical structural overhang against internal forces.

4. Supply Chain Scale: Sourcing Directly from a 700-Person Factory

Relying on small workshops creates supply chain vulnerability. Luxora eliminates this risk with a workforce of 700+ professionals and 17 high-speed production lines.

The Strategic Labor Buffer

When a manufacturer with 40 employees loses key technicians during a peak season, production halts.

Our scale provides a labor buffer that prevents the paralysis common in smaller facilities.

Furthermore, direct manufacturing removes the “trading company tax,” protecting your margins by cutting out the middleman markup.

-

Monthly Output: 800,000 units ensure massive scaling capability.

-

Stock Turnover: 3-7 day lead times for best-selling stock items.

-

Custom Orders: 15-25 day cycles for mass production, significantly faster than the industry average.

5. Eliminating Contaminants with “Pure Air” Manufacturing

Safety starts before the silicone is even injected. Luxora enforces ISO 8573.1 Class 2 standards for industrial air quality.

Standards for Industrial Air Purity

In standard facilities, moisture accumulation in compressed air lines creates a breeding ground for bacteria.

We utilize desiccant dryers and specialized filtration to maintain dew points at -40°C, ensuring environmental pollutants never compromise the biocompatibility of our medical-grade materials.

The Financial ROI of 0% Defect Rates

Standard market data indicates a 1.4% safety defect baseline for adult products.

While this may be acceptable in other sectors, in the anal play category, a 1.4% failure rate is a catastrophic liability.

By reducing defect rates to near-zero through our Triple-Inspection SOP (Incoming, In-Process, and Final QC), we hedge against the hidden costs of reverse logistics and administrative processing for failed units.

Engineered LGBTQ+ Wellness Tech For High ROI

Final Thoughts

Sustainable B2B growth in the gay anal sex toys category demands product safety that withstands rigorous chemical and mechanical scrutiny.

Sourcing porous “jelly” or standard PVC toys creates immediate liability.

Adhering to medical-grade platinum silicone and ISO 3533 engineering protocols protects your brand from costly recalls and reputational damage.

Frequently Asked Questions

Why is a ‘flared base’ a legal requirement for B2B?

Tort law identifies defective design as a primary target for lawsuits.

Objects without a base at least 50% wider than the shaft can be pulled past the sphincter by the “vacuum effect,” leading to emergency surgical extractions.

How do I verify a factory’s safety data?

Never rely on self-declarations.

Request valid third-party lab reports (SGS/TUV) for RoHS compliance and FDA 21 CFR 177.2600.

Always cross-reference the batch codes on the reports with your specific production run.

What makes Luxora’s motors superior for anal toys?

Anal devices face significant internal muscle pressure.

Generic iron-core motors often stall or overheat under load. We exclusively utilize High-Torque Tungsten Motors, stress-tested for 10,000+ cycles to ensure they maintain power without failure.

What technical specs define a high-quality manufacturer?

Look at the motor and the PCB finish.

While standard factories use Zinc-Alloy motors and HASL (Tin Spraying) boards, we exclusively engineer with High-Torque Tungsten Motors, tested for 10,000+ cycles to withstand internal muscle pressure without stalling.

For connectivity, specifically in smart devices, we use multi-layer PCBs with an ENIG (Immersion Gold) finish.

This prevents oxidation and ensures stable app connectivity, a critical requirement for high-end B2B distribution.