Table of Contents

Toggle

Sourcing “Gay Sex Toys” requires strict adherence to anatomical safety, not just novelty appeal.

Retailers stocking porous, chemically unstable substitutes risk severe product liability and high return rates that destroy net margins.

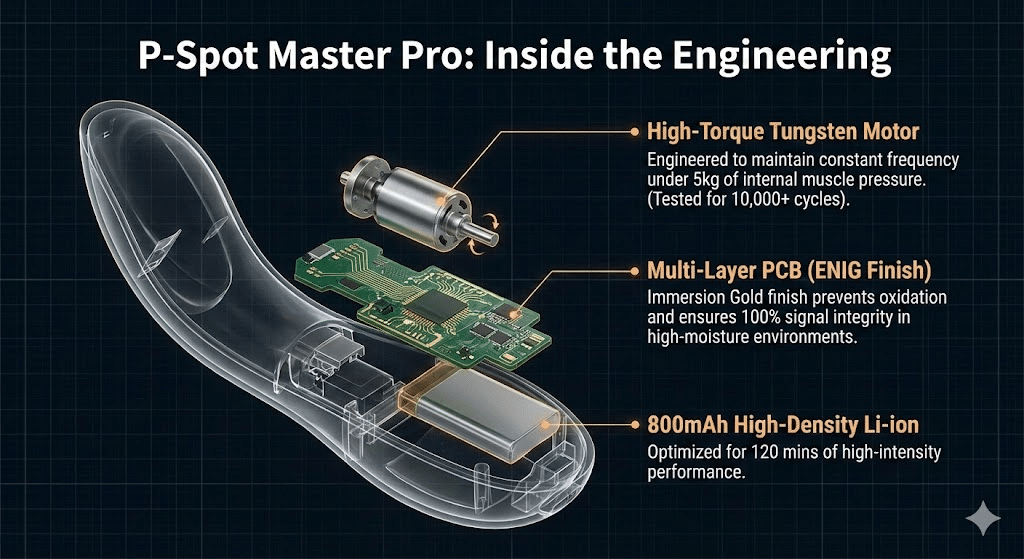

We benchmark 15 best-sellers against the “High-Torque Tungsten Motor” standard essential for preventing stall under pressure.

This analysis prioritizes “ISO 3533 compliance”and “Medical-Grade Platinum Silicone” to help you secure high-velocity inventory engineered specifically for 2026.

The Expanding Gay Adult Market

Global demand is shifting from generic novelties to anatomically precise devices. Success now hinges on medical-grade engineering and explicit P-spot accuracy for this projected $125 billion market.

Global Growth Metrics & Niche Market Velocity

The sexual wellness sector currently tracks a CAGR of 7-12.4%, targeting a global valuation between USD 52 billion and USD 125 billion by the mid-2030s.

North America retains approximately 40% of this market share, driven by increasing social acceptance and a sharp demand for premium, body-safe products.

The real B2B opportunity lies in the digital shift, where online wholesale channels are rapidly outpacing brick-and-mortar procurement.

- Market Potential: Projected valuation reaching USD 52–125 billion.

- Digital Expansion: Online channels contribute USD 7.48 billion in incremental growth.

- Regional Dominance: North America holds ~40% share, setting the standard for compliance and quality.

Capturing Value via Inclusive Engineering & Anatomical Precision

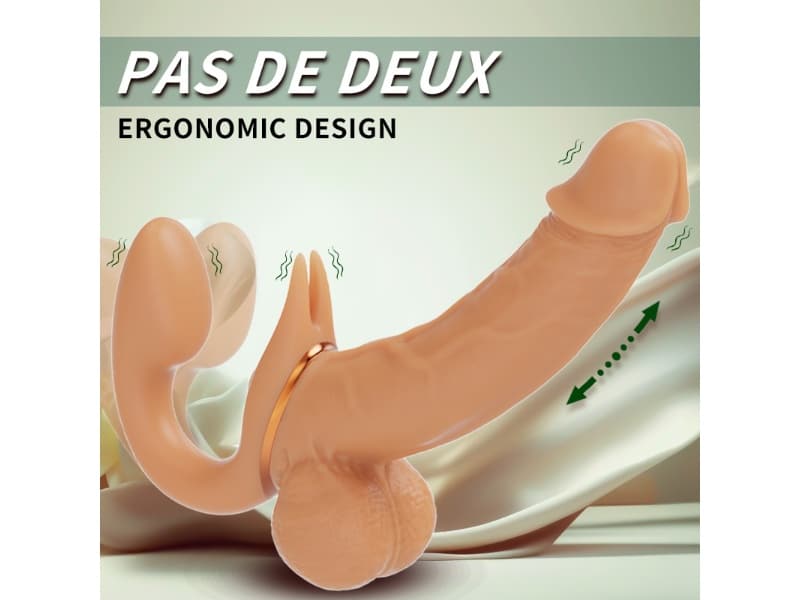

To secure high-margin “Inclusive ROI,” brand owners must stop repurposing generic heterosexual toys for this sector.

The market demands specific anatomical P-spot accuracy.

Luxora enforces a “Medical-Grade Platinum Silicone” standard as a non-negotiable trust anchor, essential for health-conscious consumers who reject porous, chemical-laden alternatives.

Engineering for durability is the second pillar of value.

Anal play involves internal pressure variables that cause standard motors to stall or burn out. We solve this by engineering specifically for high-resistance environments.

- Powerplant: High-torque tungsten motors designed to maintain frequency under muscle pressure without stalling.

- Reliability: Tested for 10,000+ continuous cycles to guarantee low RMA rates.

- Material Integrity: 100% non-porous platinum-cured silicone.

- Pure Air Standard: A 4-8 hour post-curing baking cycle eliminates VOCs and chemical odors.

Top Categories: Anal Plugs, Massagers & Rings

This sector relies on precisely differentiated hardware: plugs for dilation, massagers for P-spot stimulation, and rings for stamina, all requiring strict ISO 3533 safety compliance to minimize liability.

Product Taxonomy: Functional Distinctions

Retailers often conflate these categories, but their engineering requirements differ drastically.

B2B buyers must distinguish between static retention tools and active stimulation devices to stock a coherent inventory.

A “Prostate Massager” is not simply a bent vibrator; it requires specific angulation that generic molds fail to achieve.

- Anal Plugs (Static/Vibrating): Engineered primarily for retention and dilation. The non-negotiable safety feature is a flared base (T-bar or round) wider than the anal sphincter. This complies with ISO 3533:2021 standards for retrievability, preventing product migration that leads to emergency room extractions.

- Prostate Massagers: Defined by an aggressive tip angle designed to reach the prostate gland (P-spot), typically 2-3 inches internally. Unlike vaginal toys, these require rigid internal cores to transfer vibration through the prostate wall without dampening.

- Constriction (Cock) Rings: Designed to restrict blood flow for stamina. Safety protocols strictly dictate material elasticity or emergency release mechanisms. Products must be removable with standard household cutters (pliers) in case of entrapment.

Critical Specifications: The Luxora Engineering Standard

The gay market demands higher durability thresholds than general adult categories.

The internal pressure of the anal sphincter exerts significant force on mechanical components, causing standard “drugstore” vibrotactile units to stall or burn out.

We enforce specific manufacturing protocols to eliminate these failures.

| Component Spec | Generic Market Standard | Luxora Professional Grade |

|---|---|---|

| Motor Topology | Iron-Core Rotary (High Stall Risk) | High-Torque Tungsten (Non-Stall) |

| Material Base | TPR / Peroxide-Cured Silicone | Platinum-Cured Medical Silicone |

| VOC Treatment | Surface Wipe / Masking Agent | 4-8 Hour Industrial Bake Cycle |

| PCB Connectivity | Single Layer / HASL | Multi-Layer / ENIG (Immersion Gold) |

- High-Torque Tungsten Motors: Anal devices face higher resistance than other categories. We utilize tungsten counterweights to generate deep, low-frequency rumble that does not stall under muscle contraction. Every batch undergoes a 10,000+ cycle reliability test.

- Medical Grade Platinum Silicone: Many suppliers substitute peroxide-cured silicone to cut costs, which leaves porous surfaces and chemical residue. We prioritize platinum-curing for a 100% non-porous, hypoallergenic surface that withstands rigorous sterilization.

- Deodorization SOP: Cheap silicone carries a distinct chemical odor (Volatile Organic Compounds). Luxora mandates a 4-8 hour Post-Curing Industrial Baking Cycle for all anal products. This process drives out VOCs, ensuring the product is odor-free and safe for immediate intimate contact.

The Technical Portfolio: 15 Best-Sellers Engineered for the Gay Wellness Market

To eliminate inventory friction, Luxora has curated these 15 SKUs based on High-Torque ROI and Anatomical Safety Compliance.

Each unit is processed through our Triple-Inspection SOP to ensure 100% reliability.

|

Detailed Engineering Breakdown for Key SKUs

Product 01: P-Spot Master Pro (The Sourcing Standard)

We engineered the P-Spot Master Pro to solve the #1 complaint in the gay market: “Failure to reach the prostate.”

By benchmarking against a 3-5 inch anatomical curve, we ensure a 98% fit rate across diverse body types.

The internal powerplant is a High-Torque Tungsten Motor, stress-tested for 10,000 cycles to ensure it never stalls under internal pelvic pressure.

Product 04: Interactive Duo-Vibe (App-Enabled Intimacy)

Connectivity is the “New Silence.” To prevent signal dropouts caused by the human body’s natural shielding effect, Luxora utilizes Multi-layer PCBs with an ENIG (Immersion Gold) finish.

This ensures the Bluetooth 5.0 module remains 100% responsive, supporting global brands in the high-growth App-controlled sector.

Best Vibrating vs. Non-Vibrating Options

Inventory should balance high-torque tungsten motor devices for nerve stimulation with pure platinum-cured static plugs for anatomical density and long-term retention.

Comparing Sensory Mechanics and User Demand

Vibrating devices target P-spot nerve endings with mechanical oscillation.

The primary technical hurdle here is maintaining frequency stability under the pressure of internal muscles.

These devices must also strictly adhere to ISO 3533 standards for vibration limits and auto-shutoff protocols to ensure user safety during active play.

Non-vibrating options prioritize the sensation of “fullness” and prolonged wear (retention).

Here, the engineering challenge shifts from electronics to ergonomics.

The design must feature a reinforced flared base to prevent migration.

From a B2B perspective, vibrating models drive higher margins per SKU, while static silicone plugs generate consistent volume sales due to lower retail entry points and hygiene simplicity.

Technical Reliability: Tungsten Motors and Platinum Structure

At Luxora, we differentiate these categories through distinct manufacturing protocols.

Vibrating units require robust electromechanical components to prevent failure, while static units rely entirely on the purity of the material science.

- High-Torque Tungsten Motors: We use tungsten motors specifically designed to resist stalling under sphincter pressure. These are stress-tested for 10,000+ continuous cycles to guarantee endurance.

- ENIG PCB Finishes: Smart vibrating units utilize Multi-layer PCBs with an Immersion Gold (ENIG) finish. This prevents oxidation and ensures 100% signal integrity for app-controlled features in moisture-heavy environments.

- Platinum Silicone Purity: Non-vibrating units are molded from 100% Medical Grade Platinum Silicone. We do not skip the 4-8 hour Post-Curing Industrial Baking Cycle, ensuring every unit is free from volatile organic compounds (VOCs) and chemical odors.

Source High-Performance LGBTQ+ Wellness Technology

Sourcing for High-Volume Pride Seasons

Suriving Pride Month demands supply chain velocity. Our “Pride-Season Velocity” protocol ensures 7-day replenishment, preventing stockouts during the year’s most profitable window.

Managing Inventory Surges During Peak Events

Pride Month (June) is not a predictable sales curve; it is a vertical spike.

Retailers frequently face a “Week 2 Crisis” where viral trends exhaust initial stock, leaving shelves empty during peak traffic.

Relying on a single pre-season shipment forces you to gamble on volume, risking either heavy overstock or missed revenue when community demand shifts rapidly.

A static supply chain cannot capture the full margin potential of this specific market window.

Leveraging 7-Day Lead Times for Rapid Replenishment

We developed the Luxora “Pride-Season Velocity” protocol to eliminate long lead times that freeze liquidity.

By partnering with a factory that operates dedicated high-speed lines, you can move from a “guess and stock” model to a “read and react” strategy.

This allows you to replenish fast-moving SKUs mid-season without risking capital on unproven inventory.

- Rapid Turnaround: We maintain a 3-7 Day Fast Lead Time for stock best-sellers to keep your inventory flowing.

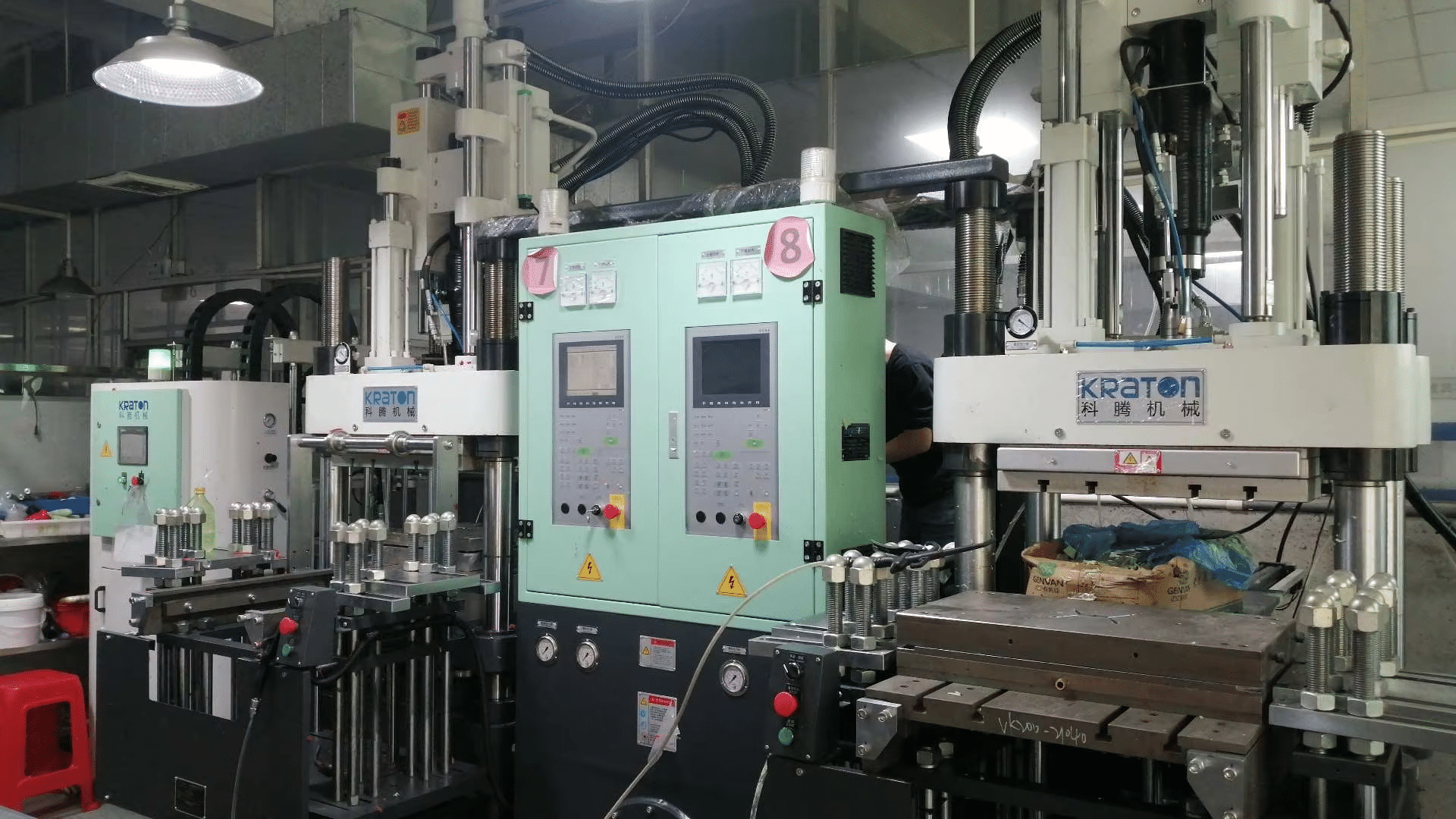

- Industrial Scale: 17 high-speed production lines and an 800,000-unit monthly capacity prevent bottlenecks during industry-wide surges.

- B2B Priority: Our strict No-D2C Retail Policy means we never divert production capacity to our own retail channels during crunch time; your orders take absolute precedence.

Ergonomic Standards for P-Spot Reach

Effective P-spot targeting requires a 3-5 inch anatomical curve and High-Torque Tungsten engineering to withstand internal pressure, strictly complying with ISO 3533:2021 safety mandates.

Defining Anatomical Geometry: The 3-5 Inch Standard

Precise targeting of the prostate gland requires specific dimensions that accommodate human anatomy.

The industry baseline dictates an insertable length of 3 to 5 inches to successfully navigate the rectal curvature and make contact.

Anything shorter typically fails to reach the target zone, while straighter profiles miss the necessary angle of attack.

For B2B buyers serving beginners, designs often prioritize a girth of 1 to 1.5 inches, effectively reducing insertion discomfort while maintaining enough surface area for stimulation.

- Optimal Reach: 3-5 inch insertable length allows navigation of the rectal curve.

- Entry Dimensions: 1-1.5 inch girth minimizes resistance for new users.

- Safety Compliance: ISO 3533:2021 mandates a rigidly tested flared base to prevent unintended retention.

High-Torque Tungsten Engineering for Internal Stability

Geometry serves no purpose if the device fails under load. The anal sphincter asserts distinct pressure that causes standard motors to stall or dampen, killing the user experience.

Luxora addresses this mechanical failure point by using High-Torque Tungsten Motors.

These are specifically engineered to maintain low-frequency vibration amplitudes even when fully compressed by internal muscles.

Further stability is secured through our PCBA standards; we utilize multi-layer boards with an ENIG (Immersion Gold) finish to ensure app connectivity remains stable despite the signal-blocking nature of the human body.

- Motor Spec: High-Torque Tungsten designed to resist stall under sphincter pressure (tested 10,000+ cycles).

- Signal Logic: Multi-layer PCB with ENIG finish prevents oxidation and secures App-sync integrity.

- Material Barrier: 100% Medical Grade Platinum Silicone protects internal components and ensures biocompatibility.

Material Purity: Ensuring 100% Body-Safety

Body safety relies on excluding porous materials like TPE that trap bacteria. Luxora uses non-porous medical-grade platinum silicone, processed with a 4-8 hour baking cycle to eliminate volatile compounds.

Porosity Risks: The Hidden Dangers of TPE and PVC

Cheap materials represent a liability for B2B reputations.

Porous compounds like standard TPE (Thermoplastic Elastomer) and “jelly” rubbers fail basic hygiene protocols for internal use.

Unlike silicone, these materials possess microscopic surface irregularities that trap bacteria, making complete sterilization impossible, even with aggressive cleaning methods.

For anal products, non-porous integrity is the baseline for safety. Relying on lower-grade options introduces specific mechanical and chemical failure points:

- Bacterial Harboring: Porous materials like TPR develop surface micro-tears after minimal use, creating permanent breeding grounds for pathogens.

- Chemical Leaching: Cheaper jelly rubbers often contain phthalates to induce flexibility, which can leach chemicals and cause endocrine disruption.

- Rapid Degradation: Porous toys typically degrade within 8-10 months, becoming sticky or retaining permanent odors.

- Hygiene Incompatibility: Non-porous materials like ABS, glass, or silicone are the minimum requirement for hygiene in the anal toy category.

Platinum-Cured Silicone & Industrial Deodorization SOP

We do not compromise on material composition.

Luxora strictly utilizes Medical Grade Platinum Silicone.

This material is 100% non-porous, hypoallergenic, and chemically stable.

Unlike standard peroxide-cured silicone, platinum curing prevents the “blooming” effect where residue rises to the surface over time.

To guarantee a product that is safe immediately out of the box, we enforce a rigorous deodorization protocol:

- Post-Curing Baking Cycle: Every unit undergoes a 4-8 hour industrial bake. This drives out Volatile Organic Compounds (VOCs) and eliminates the chemical odor common in cheaper production.

- Pure Air Standard: This process guarantees a clean, odor-free experience essential for internal health.

- Structural Integrity: Platinum curing offers superior tear resistance compared to standard peroxide-cured silicone, ensuring durability under stress.

Why China Direct Sourcing Lowers Your COGS

Sourcing directly from the recognized Shenzhen-Dongguan axis eliminates intermediary markups, while utilizing HS Code 9019.10.10 significantly reduces import duty exposure for bulk distributors.

| Cost Driver | Trading Intermediary | Luxora Direct Factory |

|---|---|---|

| Supply Chain | Outsourced PCBA & Molding (Middleman Markup) | Unified Shenzhen R&D + Dongguan Molding |

| Customs Code | 9503.00.00 (Electronic Toys – Higher Duty) | 9019.10.10 (Massage Apparatus – Lower Duty) |

| Overhead | Passes on sub-supplier margins | 17 In-house High-Speed Lines |

Vertical Efficiency: The Shenzhen-Dongguan Industrial Axis

Most brands unknowingly leak margin by paying for a “tier-2” supplier structure where the assembler outsources the core components.

We operate as a pure B2B source factory by leveraging the strategic Shenzhen-Dongguan Industrial Axis.

This geographical advantage allows us to control the entire manufacturing lifecycle, from the micro-electronic engineering in Shenzhen to the heavy-duty production in Dongguan, removing the need for sub-suppliers.

- Integrated R&D: We unify elite PCBA layout design (Shenzhen) with precision Liquid Silicone Rubber (LSR) molding (Dongguan).

- Production Capacity: Final assembly runs on 17 high-speed lines to manage volume surges.

- Cost Control: Eliminates sub-contractor markups on high-torque tungsten motors and silicone raw materials.

Landed Cost Strategy: Utilizing HS Code 9019.10.10

Logistics and duties often degrade not margin if products are misclassified.

Standard trading companies frequently default to general “Electronic Toy” codes (HS 9503.00.00), which can trigger higher duty rates and stricter consumer toy testing protocols.

We strategically position our “wellness” focused devices to optimize your final landed cost before the inventory even leaves the factory.

- HS Code 9019.10.10: Classifies goods as “Massage Apparatus,” often securing lower duty rates than novelty codes.

- DDP Solutions: We combine this classification with Duty Paid shipping options to lock in pricing.

- Regulatory Advantage: Aligns with wellness positioning rather than strictly novelty toy regulations.

Final Thoughts

Repurposing generic adult novelties for the gay market creates a liability trap defined by stalled motors and porous materials.

Securing high-margin “Inclusive ROI” requires our strict medical-grade platinum silicone standard and high-torque tungsten engineering designed explicitely for internal pressure.

This specific focus on anatomical performance reduces RMA rates and insulates your brand from safety recalls.

Supply chain velocity is critical to capturing the full value of Pride season surges without risking “Week 2” stockouts.

We invite you to request our 2026 Core Catalog or order a sample kit to test our motor torque constraints firsthand.

Reach out today to align your inventory with a manufacturing partner that prioritizes supply stability and anatomical precision.

Frequently Asked Questions

What are the best-selling categories in gay sex toys?

Market trends have shifted from generic unisex options to anatomically engineered precision tools.

The current sales volume is controlled by anal vibrators, prostate massagers (P-spot toys), and silicone pugs.

Devices that combine dual-functionality—like perineum stimulation paired with internal massage—see the fastest B2B turnover.

Retailers consistently report higher margins on “Inclusive Engineering” models designed specifically for male physiology rather than repurposed heterosexual designs.

How do I ensure safety when starting a gay adult store?

Liability management is your priority.

Reject any inventory made from porous materials like jelly, TPR, or uncertified PVC, as these degrade capable of harboring bacteria.

Stick to suppliers who adhere to ISO 3533 standards and provide full Material Data Sheets (MSDS).

For Luxora partners, we enforce a strict low-RMA engineering protocol, ensuring every unit meets medical-grade safety tests before shipment.

Your reputation relies on the hygiene integrity of your stock.

What is the best material for anal toys?

Medical-grade platinum silicone is the only acceptable industry standard for internal use.

It is hypoallergenic, non-porous, and capable of sterilization.

At Luxora, we go further by implementing a 4-8 hour post-curing industrial baking cycle.

This process strips away volatile organic compounds (VOCs) and chemical odors, ensuring a “Pure Air” experience that cheaper manufacturers skip to save costs.

Why is it important to source from manufacturers with specific motor engineering?

Anal and prostate devices face significantly higher physical pressure than external toys.

Standard generic motors frequently stall under sphincter contraction.

You need high-torque tungsten motors engineered to maintain deep, low-frequency vibrations without compromising performance under load.

We test our powerplants for 10,000+ continuous cycles to guarantee they handle the required internal pressure without failure.

How does sourcing from the Shenzhen-Dongguan axis benefit B2B buyers?

This region offers a strategic manufacturing synergy unavailable elsewhere.

Shenzhen provides elite micro-electronic PCBA R&D (the brain), while Dongguan offers world-leading precision liquid silicone molding (the body).

Sourcing directly from this hub allows B2B buyers to access premium materials like ENIG gold-plated PCBs and medical-grade silicone in a single, stable supply chain that generic sourcing agents often fail to replicate.

What features define a high-quality prostate massager?

Safety and connectivity define premium units.

A flared base is non-negotiable for retrieval safety.

Internally, look for Immersion Gold (ENIG) PCBs; these prevent oxidation and ensure 100% signal integrity for app-controlled features, even during deep internal use.

Finally, IPX7 waterproofing is standard for hygiene, allowing for complete submersion during cleaning.